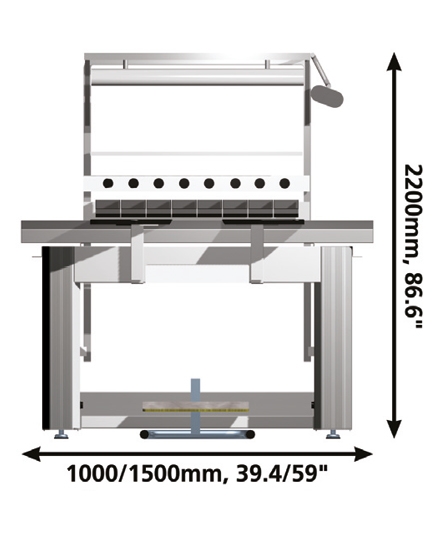

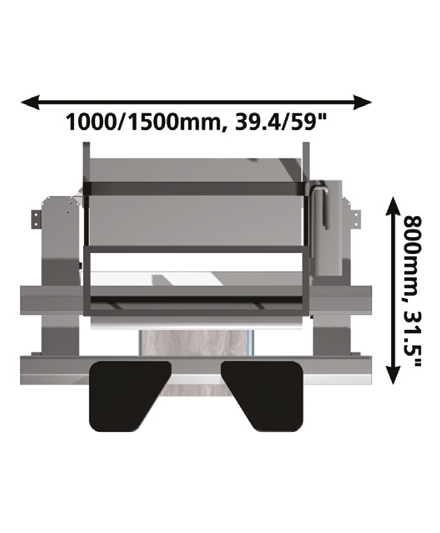

Workstation T3/T4

The T3/T4 workstation is built around the standard T3 conveyor and enables manual assembly work and inspections to be carried out on PCBs in-line. Each side and section of the conveyor has its own motor and belt, providing smooth and reliable transportation of PCBs.

Communication with preceding and following units is done via the standard SMEMA interface, which makes the conveyor easy to install in an electronics assembly line.

Width adjustment is motorized as standard. Motors and cables are housed in the conveyor profi le, giving a clean outlook to the unit. The conveyor frame is used for housing connectors, PLC and associated control electronics.

Order codes:

Workstation T3 1000mm, K-017-0533

Workstation T3 1500mm, K-017-0535

Workstation T4 1000mm, K-017-0534

Workstation T4 1500mm, K-017-0536

Standard features

- Board stop function, board release, arm rests

- Stable and ridgid construction

- PLC controlled

- Motorized width adjustment

- SMEMA interface

Options

- Adjustable transport speed

- Automatic width adjustment

- Framework with lighting, boxes, shelves

- Board release foot pedal

- See order guide for more options

- Board transport level: 940 ± 30 mm (37 ± 1.2”)

- Buffering zones T3: 1000mm = 2, 1500mm = 3

- Buffering zones T4: 1000mm = 1, 1500mm = 2

- Board length T3: 70 - 470 mm (2.8 - 18.5”)

- Board length T4: 70 - 640 mm (2.8 - 25.2”)

- Board width: 50 - 508 mm (2 - 20”)

- Min. board thickness: 0.7 mm (0.028”)

- Max. board weight: 3 kg (6.6 lbs)

- Board edge clearance: 3 mm (0.12”)

- Top/bottom clearance: 25/20 mm (1.0/0.8”)

- Max. board warpage width: 0.5%

- Voltage: 100 - 240 VAC, 50/60 Hz

- Max. power consumption: 0.3 kWh

- SMEMA Interface