Dual/Triple Unloader

The Dual and Triple Unloader consists of a conveyor mounted on an Y/Z table that receives and distributes PCBs from an upstream machine into two or three magazines, depending on selected work mode. If the pass/fail function is activated, “good” and “not good” PCBs will be separated and stored in different magazines.

Order codes:

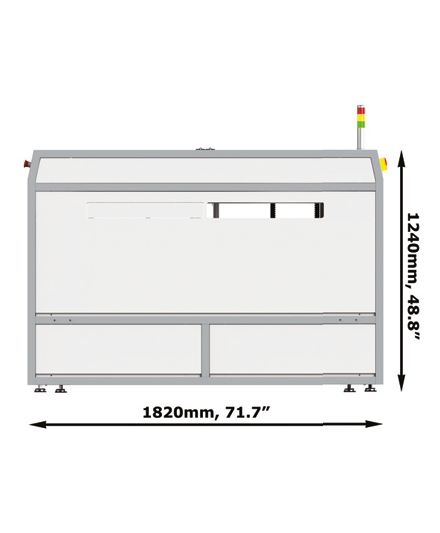

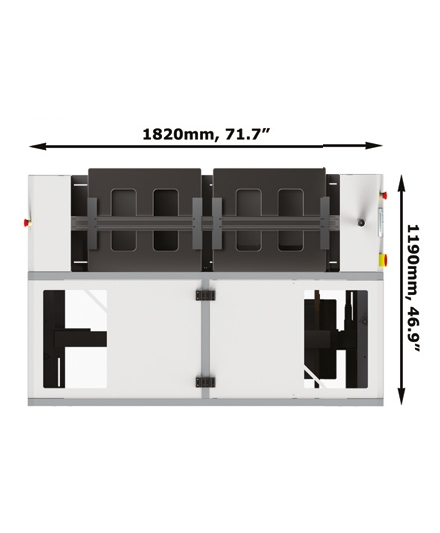

Dual Unloader, K-017-0836

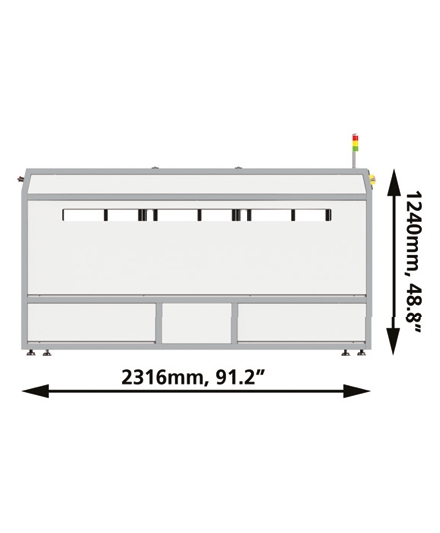

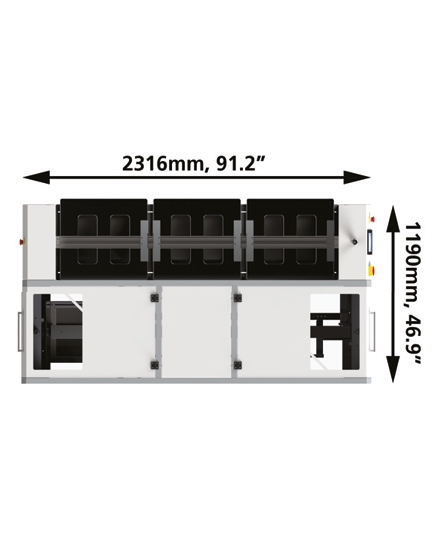

Triple Unloader, K-017-0891

Standard features

- Two modes of operation - Multi mag. Unloader and pass/fail separation

- Servo controlled Y/Z positioning

- Fully programmable shuttle conveyor input/output positions

- Board pass/fail function

- Automatic width adjustment

- PLC controlled

- SMEMA interface with OK/NG signalling

Options

- See order guide

- Board transport level: 940 ± 30 mm (37 ± 1.2”)

- Max. board size: L: 600 mm (23.6”) - W: 508 mm (20”)

- Min. board thickness: 0.7 mm (0.028”)

- Max. board weight: 3 kg (6.6 lbs)

- Board edge clearance: 3 mm (0.12”)

- Top/bottom clearance: 25/20 mm (1.0/0.8”)

- Max. magazine depth: 630 mm (24.8”)

- Max. magazine width: 580 mm (22.8”)

- Max. magazine height: 570 mm (22.4”)

- Voltage: 200 - 240 VAC, 50/60 Hz

- Max. power consumption: 0.8 kWh

- Air supply: 5-10 bar, 600 l/h (70-140 psi, 0.35 cfm)

- SMEMA Interface

Powered by Phoca Cart